Folks,

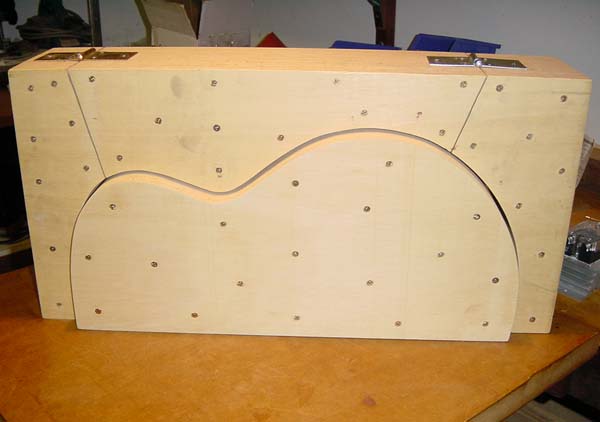

Inspired by Tom Durr (AKA Mandomaniac) who is a member here at the OLF but post mostly over at the forum without the "S", I have made a 2 part bending form.

It has a male section, minus side and metal slat thickness, which fits into a female section, minus metal slate and heat blanket thickness.

The female form is hinged in 2 places, one being at a point just forward of the apex of the upper bout, and another at a point just to the rear of the apex of the lower bout. The splitting of the female form allows the waist to be brought to bear upon the male form to start the bending process, and then the 2 bouts can be pushed down into position and clamped as required.

Because I had a sheet of 3/4 ply at hand which I bought real cheap, and did not have any MDF near by, this form has been constructed from ply. It is a SOLID form, with repetitive layers of the 3/4 ply screwed together in succession.

Open

Closed

As you can see, I also got a great deal on a couple of thousand 38mm screws

Anyhow, I now wish to seal this form and my thoughts are to force a 2 pack auto body filler into the working edges thereby filling and sealing the exposed end grain of the ply. Then maybe sand lightly, carefully maintaining the forms original shape, and spraying the sealed edge with heatproof exhaust paint.

Anyhow, I now wish to seal this form and my thoughts are to force a 2 pack auto body filler into the working edges thereby filling and sealing the exposed end grain of the ply. Then maybe sand lightly, carefully maintaining the forms original shape, and spraying the sealed edge with heatproof exhaust paint.

So, my question is, Wad ya reckon?

will my planed process seal the working edge, and handle the heat, or do you have a better idea???

will my planed process seal the working edge, and handle the heat, or do you have a better idea???

Cheers

Kim